SITE IMPROVEMENTS

In addition to the installation of traffic control systems, site and operational improvements can significantly contribute to the safety of highway-rail crossings. Site improvements are discussed in four categories: crossing geometry, removing obstructions, illumination, and safety barriers.

Crossing Geometry

The ideal crossing geometry is a 90-degree intersection of track and highway with slight-ascending grades on both highway approaches to reduce the flow of surface water toward the crossing. Few crossings have this ideal geometry because of topography or limitations of ROW for both the highway and the railroad. Every effort should be made to construct new crossings in this manner. Horizontal and vertical alignment and cross-sectional design are discussed below.

Horizontal Alignment

Ideally, the highway should intersect the tracks with a minimum skew with no nearby intersections or driveways. This layout enhances the driver's view of the crossing and tracks and reduces conflicting vehicular movements from crossroads and driveways. To the practical extent, crossings should not be located on either highway or railroad curves. Roadway curvature inhibits a driver's view of a crossing ahead, and a driver's attention may be directed toward negotiating the curve rather than looking for a train. Railroad curvature inhibits a driver's view down the tracks from both the approach to the crossing and from a stopped position at the crossing. Crossings located on both highway and railroad curves present maintenance problems and poor rideability for highway traffic if conflicting superelevation is present. Similar difficulties arise when superelevation of the track is opposite to the grade of the highway.

If the intersection between track and highway cannot be made at right angles, the variation from 90 degrees should be minimized. At skewed crossings, motorists must look over their shoulders to view the tracks. Because of this more awkward movement, some motorists may only glance quickly and not take necessary precautions.

Improvements to horizontal alignment can be expensive, depending on the extent of construction required. Special consideration should be given to crossings that have complex horizontal geometries, as described previously. These crossings may warrant the installation of active traffic control systems or, if possible, may be closed to highway traffic.

Crossing Profile –Vertical Alignment

It is desirable that the intersection of highway and railroad be as level as possible from the standpoint of sight distance, rideability, and braking and acceleration distances. Positive drainage is provided if the crossing is located at the peak of a vertical curve on the highway; however, the curve should be adequately flat to avoid hanging-up of vehicles and of sufficient length to ensure an adequate view of the crossing consistent with the highway design or operating speed.

When constructing new highway-rail at-grade crossings or enhancing existing locations, care should be taken to create horizontal and vertical profiles that provide smooth and safe travel for motorists approaching and using crossings. Vehicles or trailers low to the ground relative to the distance between axles pose the greatest risk of becoming stuck at crossings due to contact with the track or highway surface. Similarly, a low vehicle's front or rear bumper overhang may strike or drag along the pavement surface in a sag vertical curve.

The AASHTO presents a guideline which is traversable by a wide range of vehicles including those with long wheelbases and/or low ground clearance (this standard is also provided by AREMA). Shown in Figure 1, the guideline recommends that the crossing surface be in the same plane as the top of rails for a distance of 2 feet outside of the rails, and that the surface of the highway be not more than 3 inches higher or lower than the top of the nearest rail at a point 30 feet from the rail for new construction.

Source: Figure 9-102, A Policy on Geometric Design of Highway and Streets, Washington, DC, AASHTO, 2018. Used by permission.

Low-clearance vehicles pose the greatest risk of becoming immobilized at highway-rail crossings due to contact with the track or highway surface. Except for specialized vehicles such as tank trucks, there is little standardization within the vehicle manufacturing industry regarding minimum ground clearance. Instead, the requirements of shippers and operators guide manufacturers.(17)

Two constraints often apply to the maintenance of crossing profiles: drainage requirements and resource limitations. Coordination of maintenance activities between rail and highway authorities, especially at the city and county levels, can be frequently informal and unstructured. Even when the need to coordinate has been identified, there may be a lack of knowledge regarding whom to contact. For these reasons, it is important to note that with any routine track work, or any highway/roadway surface repaving work to be performed, notification of all parties, and acknowledgement of receipt of notice, should occur prior to any work commencing.

Existing crossings constructed on an embankment for drainage purposes may be problematic for low ground clearance vehicles to negotiate. Historically, track maintenance may have raised the track over time if additional ballast was placed beneath the ties. Unless the highway profile was also adjusted, this practice can result in a "humped" profile that may adversely affect the safety and operation of highway traffic over the railroad. Modern maintenance equipment and practices re-set the track structure and "tamp" the ballast in place without modifying the track elevation.

In some cases, highway authorities become aware of increases in track elevation only after maintenance activities have taken place. As a result, even if State standards exist, there is little opportunity to enforce them. Often, an individual increase in track elevation may not violate a guideline, but successive track raises may slowly create a high-profile crossing. Over time, this can result in a condition referred to as a "hump crossing."

Strategies to address this problem could include the following:

- Designing a standard with maximum grades at the crossing

- Prohibiting truck trailers with a certain combination of under-clearance and wheelbase from using the crossing

- Setting trailer design standards

- Posting warning signs in advance of the crossing

- Minimizing the rise in track due to maintenance operations

Because of the previously noted variations in vehicle configurations, it is difficult to determine whether a crossing which does not meet the AASHTO guideline is traversable by all long wheelbase and low ground clearance vehicles. Also, there are many crossings which do not meet the AASHTO guideline exactly but nevertheless are unlikely to strand low ground clearance vehicles.

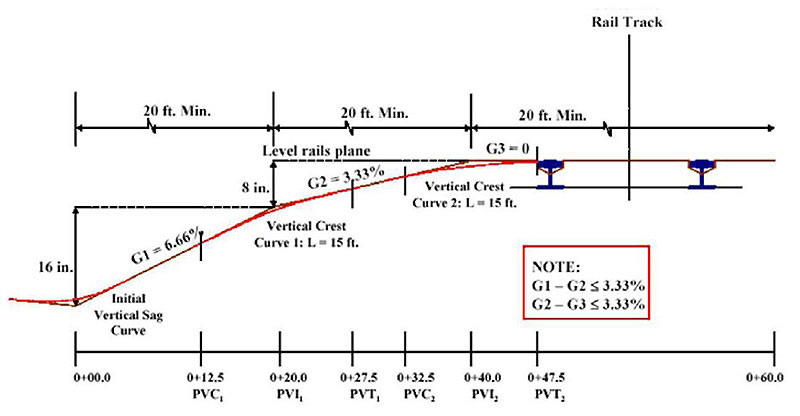

The Florida Department of Transportation (FDOT) published Design Guidelines for Highway Railroad Grade Crossing Profiles in Florida.(18) This document provides an in-depth discussion of the technical issues, lists various standards in use, and presents more practicable solutions for development of crest and sag curves which would prevent hang-up of low clearance vehicles. Figure 2 shows a crest curve treatment using three vertical curves. The project also resulted in the development of software known as HANGUP for evaluation of crossing profiles.

At locations where the profile is sufficiently abrupt to potentially immobilize vehicles, a Low Ground Clearance Grade Crossing (W10-5) warning sign and a LOW GROUND CLEARANCE (W10-5P) supplemental plaque, Figure 3, may be installed for each direction of travel to warn drivers of long wheelbase vehicles or drivers of vehicles that have a low ground clearance that they might encounter a hang-up situation if they attempt to use the crossing. (Figure 4 shows a typical treatment.) The USDOT Crossing Inventory Form(19), in Part III, Box 2E, provides a place to indicate if a crossing has such signs installed.

Source: Sobanjo, J., Design Guidelines for Highway Railroad Grade Crossing Profiles in Florida, Figure 4.6, Florida State University, May 2006.

Source: Manual on Uniform Traffic Control Devices, 2009 Edition.

Source: Seyfried, R K., (Ed.), Traffic Control Devices Handbook, 2nd Edition, Figure 11-5, Washington, DC, ITE, 2013.

Removing Obstructions and Sight Distance

Outside of urban areas, where the approach roadway has a shoulder area, it is desirable to provide a "clear zone" approaching the crossing. A clear zone is an unobstructed, traversable roadside area that allows a driver to stop safely or to regain control of a vehicle that has left the roadway.(20) This area should be free from obstacles such as unyielding sign and luminaire supports, non-traversable drainage structures, trees larger than 4 inches in diameter, utility or railroad line poles, or steep slopes. Design options for mitigating these features are generally considered in the following order:

- Remove the obstacle or redesign it so that it can be safely traversed

- Relocate the obstacle to a point where it is less likely to be struck

- Reduce impact severity by using an appropriate breakaway device

- Redirect a vehicle by shielding the obstacle by use of a longitudinal barrier or crash cushion

- Delineate the obstacle if the above alternatives are not appropriate

The term "clear zone" is also used to refer to a zone within the railroad corridor along the tracks free of sight distance restrictions. For example, Illinois regulations require a 500-foot clear zone which is to be kept "reasonably clear of brush, shrubbery, trees, weeds, crops, and all unnecessary permanent obstructions such as unauthorized signs and billboards."(21)

Adequacy of sight distance is critical at passive crossings; however, even where active devices are present or will be provided, sight distance is beneficial to confirm the ability to cross the tracks. The discussion on the following pages defines "desired" roadway user response based upon available sight distance. Drivers may not exercise best judgment under all conditions. The existence of sight distance deficiencies which cannot be corrected should consider the use of active devices at the crossing. (Refer to Appendix C for discussion of sight distance evaluation as part of a field diagnostic review of a specific crossing.)

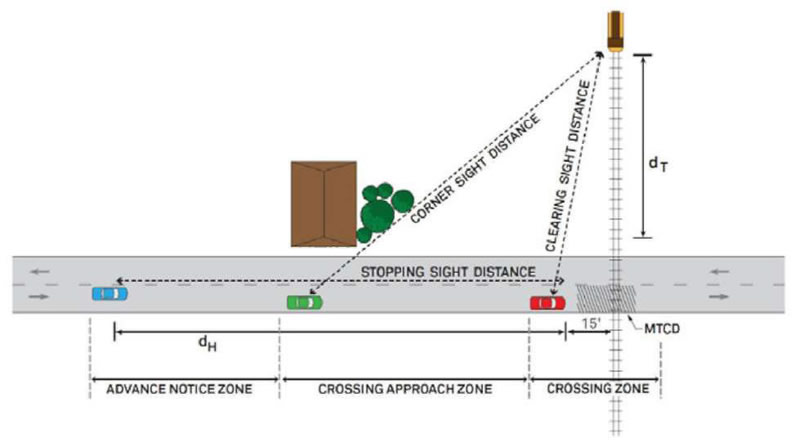

The Traffic Control Devices Handbook (2nd Edition) indicates three zones within the approach to a crossing where drivers make decisions about their movements in relation to the crossing.(2) Figure 5 shows the three zones as well as the respective sight distance associated with each (dH and dT represent the respective distances from the crossing for the highway vehicle and train, and MTCD refers to the "minimum track clearance distance" at the crossing, which should be clear of vehicles when a train is approaching). Table 2 indicates for each zone the desired roadway user response, depending upon whether a train is visible.

Source: Traffic Control Devices at Grade Crossings, Figure 11-15, Washington, DC, ITE, 2013.

It is desirable that sight distances permit operation at the design speed of the approach roadway to the greatest degree practical. To permit this, three areas should be kept free from obstruction: the advance notice zone, where the road user first realizes there is a crossing ahead, the crossing approach zone where adequate corner sight distance is desirable, and the crossing zone where clearing sight distance is required.

Table 2 highlights the Traffic Control Devices Handbook guidance for sight distance.(2)

Table 2. Sight Distance Zones

| Region | Sight Distance Criteria | Information Acquired by Roadway User | Desired Roadway User Response |

|---|---|---|---|

| Advance Notice Zone | Stopping Sight Distance | Grade crossing ahead (train may be at crossing) | Look ahead and to both sides for more information; consider safe approach speed; stop if necessary |

| Crossing Approach Zone | Corner Sight Distance | Grade crossing ahead (train may be at crossing) | Slow down; stop ahead of crossing |

| Train in crossing | Slow down; stop ahead of crossing if train may arrive at crossing before roadway vehicle can clear the Crossing Zone | ||

| Train approaching | Slow down if corner sight distance impaired; prepare to stop if necessary | ||

| Crossing Zone (including MTCD) | Clearing Sight Distance | No train visible | Stop; wait for train to pass |

| Train in crossing | Stop ahead of crossing if required to do so by law; proceed with caution if roadway user can clear the Crossing Zone before train arrival | ||

| Train approaching | Stop if required to do so by law; proceed through crossing | ||

| No train visible | Look ahead and to both sides for more information; consider safe approach speed; stop if necessary |

Approach Sight Distance

The first region of concern is the approach sight distance where the road user becomes aware of the presence of a crossing ahead. The approach area from the road user to the crossing should be evaluated to determine whether it is feasible to remove any obstructions that prevent the motorist from viewing the crossing ahead, a train occupying the crossing, or active control devices at the crossing.

Obstructions in this area can be traffic control devices, roadside commercial signing, utility and lighting poles, or vegetation. Horizontal and vertical alignment can also serve to obstruct motorists' view of the crossing. Clutter can sometimes be removed with minimal expense, improving the visibility of the crossing and associated traffic control devices. Traffic control devices unnecessary for the safe movement of vehicles through the crossing area should be relocated if possible. Vegetation should be removed or cut back periodically. Billboards should be prohibited on the approaches.

Corner Sight Distance

The second region of concern is the corner sight distance which allows an approaching road user the ability to see an approaching train. View obstructions often exist within the sight triangle, typically caused by structures, topography, crops or other vegetation (continually or seasonal), movable objects, or weather (fog or snow). Where restricted sight distances exist, motorists should reduce speed and be prepared to stop no less than 15 feet before the near rail, unless and until they are able to determine, based upon the available sight distance, that there is no train approaching and it is safe to proceed. Wherever possible, sight line deficiencies should be improved by removing structures or vegetation within the affected area, regrading an embankment, or realigning the highway approach.

Many conditions, however, may be difficult to correct because the obstruction is on private property or it is economically infeasible to correct the sight line deficiency. If available corner sight distance is less than what is required for the legal speed limit on the highway approach, supplemental traffic control devices, such as enhanced advance warning signs, or reduced speed limits (advisory or regulatory) should be evaluated. If the responsible highway authority wishes to allow vehicles to travel at the legal speed limit on the highway approach, active warning devices should be considered.

Changes to horizontal and vertical alignment can be more expensive, depending on the scope of the desired change. When constructing new highways or reconstructing existing highways, however, care should be taken to minimize the effects of horizontal and vertical curves at a crossing.

Clearing Sight Distance

The third region of concern is the clearing sight distance, which pertains to the visibility available to a road user along the track when stopped ahead of the crossing. Usually, this area is located on railroad ROW. Vegetation is often desired along railroad ROW to serve as an environmental barrier to noise generated from train movements; however, safety at crossings is of more importance and, if possible, vegetation within the rail right-of-way should be removed or cut back periodically. States or other authorities may require clear sight lines of 500 feet in each direction (refer to prior discussion on Clear Zones). Also, if practical, this sight distance area should be kept free of parked vehicles and standing railroad cars or locomotives. Care should be taken to avoid the accumulation of snow in this area.

Table 3 provides clearing sight distance for cars, trucks, and pedestrians. The person or agency evaluating the crossing should determine the specific design vehicle, pedestrian, bicyclist, or other non-motorized conveyance and compute clearing sight distance if it is not represented in Table 3 using formulas provided in AASHTO A Policy on Geometric Design of Highways and Streets, 7th Edition, Chapter 9, Section 12.(22)Note that the table values are for a level, 90-degree crossing of a single track. If other circumstances are encountered, the values should be recomputed using the equations shown in AASHTO.

Table 3. Clearing Sight Distance Criteria by Mode

| Train Speed | 73.5-foot Double Truck(a) | Car(b) | Pedestrian(b) |

|---|---|---|---|

| 10 | 255 | 105 | 180 |

| 20 | 509 | 205 | 355 |

| 30 | 794 | 310 | 530 |

| 40 | 1,019 | 410 | 705 |

| 50 | 1,273 | 515 | 880 |

| 60 | 1,528 | 615 | 1,060 |

| 70 | 1,783 | 715 | 1,235 |

Sources: (a) A Policy on Geometric Design of Highways and Streets, AASHTO, Washington, DC, 2018; (b) Guidance on Traffic Control Devices at Highway-Rail Grade Crossings, Highway/Rail Grade Crossing Technical Working Group, Washington, DC, 2002.

If there is insufficient clearing sight distance, and the driver is unable to make a safe determination to proceed, the clearing sight distance needs to be improved to safe conditions or flashing-light signals with gates, closure, or grade separation should be considered.

An engineering study should be conducted to determine if the three types of sight distance can be adequately provided. If not, other alternatives should be considered. The posted highway speed might be reduced to a level that conforms to the available sight distance. It is important that the motorist understand why the speed reduction is necessary, otherwise, it may be ignored unless enforced. At crossings with passive control devices only, consideration might be given to the installation of active traffic control devices that warn of the approach of a train.

Illumination

Illumination at a crossing may be effective in reducing nighttime collisions. Illuminating most crossings is technically feasible because nearly all crossings have commercial power available. Illumination may be effective under the following conditions:

- Nighttime train operations

- Low train speeds

- Blockage of crossings for long periods at night

- Collision history indicating that motorists often fail to detect trains or traffic control devices at night

- Horizontal and/or vertical alignment of highway approach such that vehicle headlight beam does not fall on the train until the vehicle has passed the safe stopping distance

- Restricted sight or stopping distance in rural areas

- Humped crossings where oncoming vehicle headlights are visible under trains

- Low ambient light levels

- A highly reliable source of power

Luminaires may also provide a low-cost alternative to active traffic control devices on industrial or mine tracks where switching operations are carried out at night.

Figure 6 shows a typical layout where a minimum of two luminaires are placed in opposite approach quadrants to illuminate the crossing and a 100-foot approach zone. Luminaire supports should be placed in accordance with the principles in the Roadside Design Guide(23) and the Manual for Assessing Safety Hardware(24). If they are placed in the clear zone on a high-speed road, they should be breakaway.

Source: Institute of Transportation Engineers.

Illumination guidance for crossings is provided in the ANSI/IES publication RP-8-14.(25)Illumination requirements for the 100-foot approach zone range from 3 lux (concrete) to 9 lux (smooth asphalt). According to the ANSI/IES RP-8-14, there are several factors affecting visibility. As these factors heighten/increase, the visibility level of the target can significantly increase or decrease. The factors which should be taken into consideration include the following:

- Adaptation level–relative contrast sensitivity

- Age of the observer

- Contrast

- Disability glare

- Size

- Time of viewing

- Transient adaptation

Safety Barriers and Crossing Surfaces

Guardrails and Crash Cushions

The purpose of a traffic barrier, such as a guardrail or crash cushion, is to protect the motorist by redirecting or containing an errant vehicle. The purpose is not to protect a traffic control device against collision and damage. The use of a traffic barrier should be limited to situations in which hitting the object, such as a traffic control device, is more hazardous than hitting the traffic barrier and redirecting the vehicle into a train.

Longitudinal guardrails should not be used for traffic control devices at crossings unless the guardrail is otherwise warranted, such as for a steep embankment. The longitudinal guardrail might redirect a vehicle into a train. The ring type guardrail placed around a signal mast may be used at locations with heavy industrial traffic, such as trucks, and low highway speeds. Care should be taken not to create the same type of hazard as the signal mast itself (the guardrail may be a roadside obstacle).

On some crossings, it may be possible to use crash cushions to protect the motorist from striking a traffic control device. Some crash cushions are designed to capture rather than redirect a vehicle and may be appropriate for use at crossings to reduce the redirection of a vehicle into the path of a train.

A curb over 4 inches in height is not an acceptable treatment where vehicle speeds are high because it may cause vehicles to become airborne if struck at high speed. Curbs should be avoided on high-speed roads but, if needed, the curb can be located at the back of the shoulder. In some cases, curbs closer to the traveled way may be acceptable on a high-speed road where they fulfill an important function, such as blocking an illegal or undesirable traffic movement.

The Manual for Assessing Safety Hardware (MASH)(24) developed by AASHTO provides current standards for upgrading barriers, crash cushions, and other features. The AASHTO/FHWA jointly established an initiative in 2015 to upgrade existing highways to conform to the MASH standards. More information can be obtained from the Roadside Design Guide.(23) An engineering study should be completed to help determine the appropriate barrier treatment.

Crossing Surfaces

The AREMA Manual of Railway Engineering, Chapter 5, Part 8,(26) provides guidelines for the construction and reconstruction of highway-rail crossings. The first section of Part 8 provides information on the following crossing surface materials:

- Crossing width

- Profile and alignment of crossings and approaches

- Drainage

- Ballast

- Ties

- Rail

- Flange widths

- New or reconstructed track through a crossing

Proper preparation of the track structure and good drainage of the subgrade are essential to good performance from any type of crossing surface. Excessive moisture in the soil can cause track settlement, accompanied by penetration of mud into the ballast section. Moisture can enter the subgrade and ballast section from above, below, and/or adjacent subgrade areas. To the extent feasible, surface and subsurface drainage should be intercepted and discharged away from the crossing. Drainage can be facilitated by establishing an adequate difference in elevation between the crossing surfaces and ditches or embankment slopes. The highway profile at all crossings should be such that water drains away from the crossing.