APPENDIX C: MAINTENANCE GUIDANCE

As resources (funding, staff, and equipment) allow, the following best practices are recommended as part of a regular maintenance program. Conduct an annual or biannual review of all W-beam guardrail in a jurisdiction. Keep a record of the inspection by date and person carrying out the inspection. This will be helpful in the event of a lawsuit resulting from a crash. Look for the following features:

- Continuity of tension is preserved: no tears in the W-beam elements, all eight bolts are in each splice; all transitions are firmly connected to rigid objects; anchor cables are firmly attached to rail and posts.

- Rail height is adequate. Erosion and debris buildup can affect the effective rail height. Identify rail significantly low – 24 inches or less –or rail significantly high – more than 30 inches –for upgrading or modification, as resources permit.

- Integrity of the material is sound: no significant corrosion of the steel in the rail elements (especially watch for rusting steel), the offset blocks, or the posts, and no significant rotting of wood material.

- The amount of guardrail in advance of the hazard (length of need) is long enough to adequately shield the hazard.

- Identify older, nonstandard W-beam (or other types) systems (such as nonblocked out rail).

- For end treatments, ensure post #1 is sound and connected to its foundation.

- For energy-absorbing end treatments, the impact head is attached to post 1.

- The grading around the end treatment allows a small vehicle impacting on the end to pass over any remaining foundation/post/strut.

- Ensure adequate, available deflection distance (generally 3 ft for the standard W-beam system) to vertical rigid objects.

- Flare (the rate at which the guardrail moves closer to the travel way going downstream) is not excessive (not sharper than 7:1).

- Check for adequate soil backing (1ft of 3:1 or flatter soil for standard 6-ft posts) to provide the stiffness for the posts.

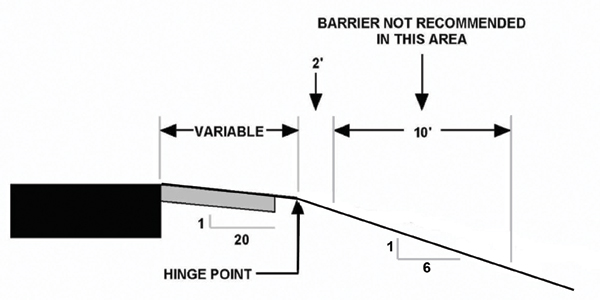

- Ensure guardrail located on a steeper slope is in compliance with the figure below in order to prevent vaulting.

- Ensure the offset blocks are not rotated.

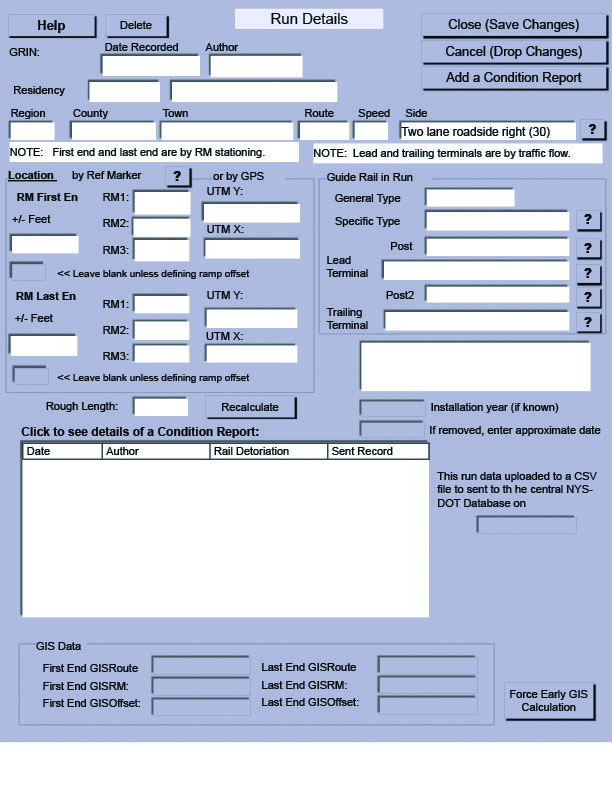

A useful tool for managing this asset is an inventory (with possibly a rating system) of existing W-beam barrier, indicating the type of W-beam (post and offset block material, rail material) and the type of end treatment (model name and materials). The inventory is also useful in setting priorities for improvement projects. The following is an example inventory system being developed by New York State DOT. For additional information on this inventory system, contact NYSDOT's Transportation Systems Maintenance, 50 Wolf Road, Albany, NY 12232; phone: 518-457-6435.

New York State Dot Guardrail Inventory System Report.