Preface

In 2013, there were approximately 5.6 million crashes reported across the nation, including 32,719 fatalities and over 2.3 million injuries.1 More than half of the 2013 fatalities were roadway departure crashes.

Often, a small subset of the total highway network is responsible for a significant percentage of certain crash types. In 2008, for example, 28 percent of fatal crashes occurred on horizontal curves, yet horizontal curves make up only 5 percent of our Nation's roadways. Compared to vehicles driving on a tangent road section, vehicles traversing horizontal curves require a greater lateral friction due to centrifugal forces.

A roadway must have an appropriate level of pavement friction to ensure that vehicles stay safely in their lane. Poor pavement conditions, especially wet pavement, have been identified as one of the major contributing factors in roadway departure (RwD) crashes. When a pavement surface is wet or polished from wear, the level of pavement friction is reduced which may lead to skidding or hydroplaning. A high friction surface treatment (HFST ) is an ideal countermeasure for such locations because it significantly increases pavement friction and helps prevent drivers from losing control on severe curves when at least one of the following conditions exist:

- Vehicle friction demand outweighs available pavement friction;

- Vehicles are traveling too fast for the geometric design of the curve;

- Vehicles are traveling too fast for roadway conditions (e.g. wet weather, icy); and/or

- Pavement has been polished from wear.

What is a High Friction Surface Treatment (HFST)?

"HFST's coefficient of friction lasts longer and reduces friction-related crashes better than any other pavement treatment."

— PennDOT

HFST is a safety treatment that happens to be a pavement treatment. It dramatically and immediately reduces crashes, injuries, and fatalities associated with friction demand issues. The treatment can help compensate for deficient geometric designs, such as sharp curves and/or inadequate or variable superelevations, by providing the necessary friction to maintain traction on the intended path. HFSTs can also restore pavement surface friction where traffic has polished existing pavement surface aggregates. While not a substitute for corridor repaving, HFST provides significant increases in friction for spot applications (e.g., horizontal curves, steep grades, intersection approaches).

HFST Benefits and Effectiveness

HFST effectiveness varies by location, but overall, agencies have found that HFST can improve pavement surface friction values by up to three times the existing condition, reduce needed stopping distance by 25 to 30 percent, and provide impressive crash reductions of anywhere from 45 to 100 percent. Table 1 summarizes HFST overall crash reductions for 5 States; the crash reductions are even greater for crashes during wet road conditions.

| State | Number of Sites in Study | Average Total Crash Reduction | Average Wet Crash Reduction |

|---|---|---|---|

| Kentucky | Unknown | 73% | 86% |

| South Carolina | 6 | 70% | 77% |

| Florida | 11 | 45% | 66% |

Several States have found HFST to be an ideal alternative to horizontal curve realignment, saving 90 to 98 percent in project costs.2 The treatment offers many advantages over large roadway realignment projects and other pavement treatments. These advantages include:

- Relatively inexpensive treatment. HFST is a low-cost crash reduction treatment3 capable of providing greater safety benefits than other low-cost safety measures such as advanced curve warning signs, advisory speed plaques, pavement markings, chevrons, open-graded friction course (OGFC), open graded asphalt concrete (OGAC), and guardrail when installed in appropriate locations.

- Quick implementation. Agencies can expect a relatively short planning process and installation timeframe, compared to other alternatives. Some agencies have reported installation in as little as 10 days for small applications or 6 months for larger projects.

- Minimal impact to traffic. HFST implementation requires only one lane to be closed at a time, most likely eliminating the need for a detour.4

- Negligible environmental impacts. The treatment is only applied between existing pavement edges and does not require disturbances to surrounding ground.5 This can result in shortened environmental review periods and lessen environmental mitigation.

- Durable and long lasting. HFST has excellent pavement surface functional durability, having an estimated service life from 5 to 8 years for 15,000 vehicles per day, and up to 5 years with 50,000 vehicles per day.

Purpose and Organization of the HFST Curve Selection and Installation Guide

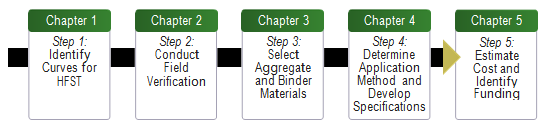

The purpose of this guide is to provide a step-by-step process for identifying potential curves for HFST implementation in order to improve horizontal curve safety and prevent friction-related crashes. The HFST Curve Selection and Installation Guide is organized as illustrated in Figure 1.

Figure 1. HFST Curve Selection and Installation Guide Chapter Organization.

1 NHTSA sponsors a Speed Program Management course that is conducted by the Transportation Safety Institute.

2 Interview with Darrell Chambers and Robert Peterson, California Department of Transportation, conducted on November 25, 2014. Interview with Joey Riddle and Brett Harrelson, South Carolina Department of Transportation, conducted on November 12, 2014.

3 Every Day Counts 2: HFST website, available at: https://www.fhwa.dot.gov/innovation/everydaycounts/edc-2/hfst.cfm.

4 Interview with Darrell Chambers and Robert Peterson, California Department of Transportation, conducted on November 25, 2014. Interview with Joey Riddle and Brett Harrelson, South Carolina Department of Transportation, conducted on November 12, 2014.

5 Interview with Darrell Chambers and Robert Peterson, California Department of Transportation, conducted on November 25, 2014.