High Friction Surface Treatments (HFST)

High friction surface treatments (HFST) are pavement treatments that dramatically and immediately reduce crashes, injuries, and fatalities associated with friction demand issues, such as:

- A reduction in pavement friction during wet conditions, and/or

- A high friction demand due to vehicle speed and/or roadway geometrics.

A research report published by FHWA shows HFST is estimated to reduce wet crashes by 83 percent and total crashes by 57 percent.

HFST involves the application of very high-quality aggregate to the pavement using a polymer binder to restore and/or maintain pavement friction at existing or potentially high crash areas. The higher pavement friction helps motorists maintain better control in both dry and wet driving conditions.

While not an answer for corridor paving, HFST is an approach that has been demonstrated nationally and internationally and has provided significant increases in friction for spot applications. State-of-the-art friction measurement equipment has been used to verify the improved friction after installation.

Features

- Visit the Case Studies and Noteworthy Practices page for information about real-world HFST applications.

- HFST frequently asked questions, specifications, and additional resources are available on the FAQs, Links, and Other Resources page.

What's New

- High Friction Surface Treatment Gets Gripping Results in Pennsylvania

- Crash Modification Factors for High-Friction Surface Treatment in Pennsylvania – Final Report

- High Friction Surface Treatment - Installation and Inspection Pocket Guide

- High Friction Surface Treatments - Frequently Asked Questions - 2022 update

- High Friction Surface Treatment — Site Selection and Installation Guide

- High Friction Surface Treatment Resources

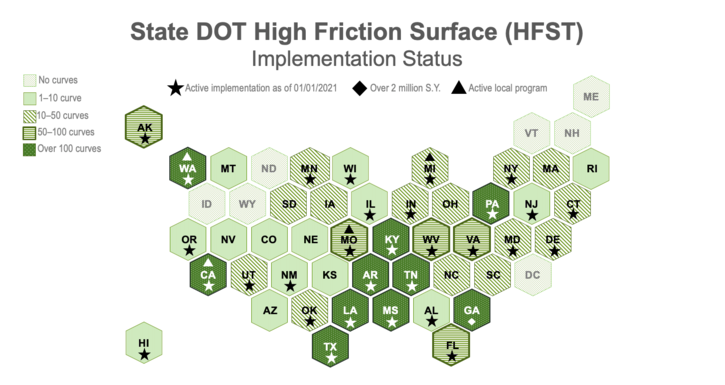

The concept of applying skid resistant surface treatments was first evaluated in the United Kingdom in 1967 for the greater London Council. The city undertook a program to improve intersections by applying a highly skid-resistant overlay at more than 800 intersections and other potential problem locations. A study of the project, entitled "The Location and Treatment of Urban Skidding Hazard Sites" (TRB Research Record 623, 1976) indicated a 31 percent reduction in crashes. The technology arrived in the United States a few decades later, but was used mainly for sealing bridge decks. It wasn't until the early 2000s that various HFST suppliers began to market the treatment as a safety countermeasure to State and local agency transportation departments. The map below shows the status of HFST implementation on curves in the United States as of December 2017.

The following links will take you to sections of this page describing more about HFST and supporting FHWA programs:

Technology Description

Recent advances in understanding pavement friction demands, epoxy formulation, and durable aggregate production are improving safety at critical high-crash spot-locations on concrete and asphalt pavements. The available HFST products use aggregates that are polish- and abrasion-resistant and reduce hydroplaning on wet surfaces.

Close-up of typical aggregate used as surface topping, showing angularity and size.

The treatments can be applied using either hand or mechanical methods. The speed of a fully mechanized HFST installation is similar to other paving surface operations. Various types of HFST systems are available based on the aggregate types, binder systems, and application methods.

HFST products are available from numerous manufacturers and contractor suppliers. Application methods and specifications can vary depending on how the product is adopted for treatment.

Appropriate Use and Locations

Maintaining the appropriate amount of pavement friction is critical for safe driving. In locations such as sharp horizontal curves and where vehicles may brake excessively, pavement surfaces may become prematurely polished, thereby reducing the available pavement friction. This friction reduction can contribute to vehicles losing control or skidding when they speed, turn abruptly, or brake excessively. HFST can restore safe friction levels to polished pavement.

Maintaining the appropriate amount of pavement friction is critical for safe driving. In locations such as sharp horizontal curves and where vehicles may brake excessively, pavement surfaces may become prematurely polished, thereby reducing the available pavement friction. This friction reduction can contribute to vehicles losing control or skidding when they speed, turn abruptly, or brake excessively. HFST can restore safe friction levels to polished pavement.

Additionally, compared to vehicles driving on a tangent section of road, vehicles traversing horizontal curves require a greater side (lateral) force friction and vehicles at intersections require greater longitudinal force friction. These areas may need greater-than-normal pavement friction.

HFST technology is unique in its ability to address site-specific issues and may also be beneficial at:

- High volume intersection approaches,

- Interchange ramps,

- Bridges, and

- Selected segments of interstate alignments.

This innovation can assist State DOTS, counties, cities, tribes, and Federal land agencies across the country to improve friction for spot locations.

Benefits

Thanks to the benefits cited below, HFST improvement projects have been well received by the public and elected officials.

HFSTs reduce crashes, injuries, and fatalities.

In 1997, Transit New Zealand reviewed the international investigatory levels of skid resistant pavement and subsequently published findings in a report titled "Investigatory Wet Road Skid Resistance Levels for New Zealand State Highway Network". The report concluded that implementation of a skid resistance policy yielded a benefit cost ratio of 40. Pre- and post-implementation studies of the skid resistance policy showed there had been a significant 30 percent reduction in the wet road crash rate.

Crash data from U.S. implementation sites are now being reported for horizontal curves that were treated with HFST in the mid-to late- 2000s. This data confirms experience from abroad, in that large reductions in vehicle crashes are being reported after installation of HFST.

Additional crash reduction analysis is currently underway as part of the FHWA's Evaluation of Low-Cost Safety Improvements Pooled-Fund Study. Kentucky has gone on to install and measure 25 additional HFST applications, and after at least one year these sites have witnessed crash reductions of 69 percent.

HFSTs are relatively low in cost compared to geometric improvements.

State DOTs report HFST costs ranging from $25 to $50 per square yard. While this is not cheap, HFST's durability makes up for the initial high cost since the treatments have at least a 10 year life-cycle.

South Carolina DOT realized an 80 percent cost savings after using HFST on a one mile segment of roadway, as compared to realignment of the same section. For more information, refer to the HFST Case Study related to South Carolina DOT's experiences.

Further, the benefit-cost ratio is high since crash reductions continue for many years.

HFSTs are durable and long-lasting.

HFSTs provide a resilient and long-term solution at locations where insufficient friction is a contributing factor in crashes and existing pavement quality is good. The expected lifecycle of HFST is approximately 10 years.

HFSTs are customizable to specific State and local safety needs.

Agencies can use HFST where it may be most useful as shown by studies and their own experience, such as:

- Two-lane urban or rural horizontal curve locations,

- Sections at or near steep grades,

- Segments at or near lane changes and merges, and

- Rural and urban intersections.

HFSTs produce measurable results.

A recent before and after study from South Carolina DOT for a series of horizontal curve installation indicates benefit-cost ratios of approximately 24 to 1.

Kentucky placed HFST on 26 horizontal curves and to-date has seen an average reduction from 6.2 to 1.9 crashes per year at those locations. For more information, refer to the HFST Case Study related to Kentucky Transportation Cabinet's experiences.

Additionally, the National Cooperative Highway Research Program (NCHRP) Report 617 indicates a crash reduction of 20 percent for all intersection crashes.

HFSTs produce negligible environmental impacts and minimal impact on traffic.

Typically, HFST installation lengths are very short and have very few environmental impacts, especially when compared to road realignments. Additionally, treatments can often be applied in hours, causing minimal traffic delays and effects as compared to a conventional pavement overlay project. For more information, refer to the HFST Case Study related to Caltran's experiences.

Every Day Counts – High Friction Surface Treatments

The Federal Highway Administration's Every Day Counts (EDC) initiative is designed to identify and deploy innovations aimed at shortening project delivery, enhancing the safety of our roadways, and improving environmental sustainability.

To ensure that the benefits of using HFST are attained quickly by a high percentage of the United States market, the EDC initiative has established an aggressive program to rapidly accelerate HFST deployment and adoption. As part of the subsequent EDC2 initiative, an implementation plan was created to serve as a roadmap for rapid, successful implementation of HFST, including technical guidance and assistance, benchmarking, marketing and communications, training, and project demonstrations that will highlight best practices.

Visit the EDC 2012 HFST web site for more information about the EDC2 HFST program and resources.

Surface Enhancements at Horizontal Curves (SEaHC) Program

FHWA began actively promoting HFST in 2008 with the creation of a national demonstration program – SEaHC. The SEaHC program provided for assistance in HFST site selection, installation of HFST, and long-term assistance in measurement of friction and texture for a limited number of pilot States. As of 3/31/2014, under the FHWA SEaHC Demonstration Program, HFST has been installed in 10 States, with a total of 23 installations being placed around the country.

Although HFST can be applied to a broad range of road scenarios, this national demonstration is focusing on locations that have been identified by FHWA as most beneficial – horizontal curves. The program will culminate with interim and final reports that document the before and after crash reduction realized for a three year period for all sites established in the program.

For more information about HFST materials, as well as specific information about the demonstration projects that will be conducted under this FHWA effort, visit: