Safety Eligibility Letter B-134C (2008)

Safety Eligibility Letter B-134C

PDF [258 MB]

U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Ave. S.E.

Washington, D.C. 20590

July 28, 2008

Reply Refer To: HSSD/B-134C

Mr. Barry Stephens

Sr. Vice President Engineering

Energy Absorption Systems, Inc.

3617 Cincinnati Avenue

Rocklin, CA. 95765

Dear Mr. Stephens:

This letter is in response to your request for Federal Highway Administration (FHW A) acceptance of a roadside safety system for use on the National Highway System (NHS).

| Name of system: | 12M Vulcan Barrier and Vulcan Barrier Anchor System |

|---|---|

| Manufacturer: | Energy Absorption Systems, Inc. (EASI) |

| Type of system: | Steel tlrie beam portable barrier system |

| Test Level: | NCHRP Report 350 TL-3 |

| Testing conducted by: | E-Tech Testing Services, Inc. |

| Date of request: | March 10, 2008 |

| Date of completed package: | March 10, 2008 |

You requested that we find this system acceptable for use on the NHS under the provisions of National Cooperative Highway Research Program (NCHRP) Report 350 "Recommended Procedures for the Safety Performance Evaluation of Highway Features."

Requirements

Roadside safety systems should meet the guidelines contained in the NCHRP Report 350, "Recommended Procedures for the Safety Performance Evaluation of Highway Features." FHWA Memorandum "Action: Identifying Acceptable Highway Safety Features" of July 25, 1997, provides further guidance on crash testing requirements of longitudinal barriers.

Description

The 12-Meter Vulcan portable longitudinal barrier segment is shown in the enclosed drawing for reference. Each segment is 8 13 mm tall × 546 mm wide × 11 ,754 mm long (32 in × 21.5 in × 38.6 ft) and weighs 1185 kg (2612 pounds). The 12M Vulcan segments incorporate six thrie beam guardrail panels integrated into both sides at a height designed to optimize vehicle redirection. The design also incorporates a lower rub rail along the entire length to help redirect the wheels of impacting vehicles. Thirteen steel bulkheads are incorporated into each segment to help distribute impact loads from one side to the other. A lifting tab is built into the top of the center bulkhead to permit easy grappling and transport. The ends of each Vulcan incorporate tabs that allow the pinning together when segments are butted together. Pinning is accomplished using 48 mm (2 in) diameter (OD) steel pins with a wall thickness of 10 mm (0.39 in). To minimize corrosion, all Vulcan components are hot dipped galvanized. When installed in continuous straight segments, a gap-filling steel plate can be added which helps the pinned joint support a bending moment, thereby reducing lateral deflection. These gap-filling steel plates were used in the crash test you submitted for review. You noted that the 12M Vulcan's end bulkheads can also be used to connect an appropriate crash cushion to protect the exposed end of a run of 12M Vulcan.

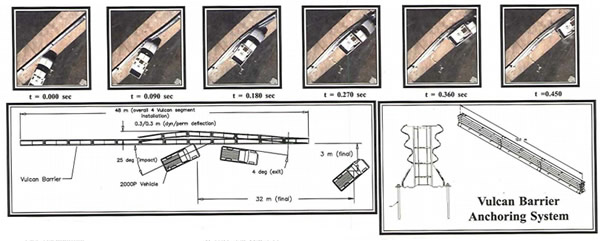

You noted that the 12M Vulcan segments used in the crash test was restrained from moving laterally by a new Vulcan Barrier Anchoring System (VAS). This system consists of a 9.5 mm x 76.2 mm (0.37 in x 3 in) ASTM A-36 steel strap that can be inserted through the base of the 12M Vulcan and then anchored to a rigid surface using (2) two 19 mm diameter by 250 mm long (3/4 in x 10 in) threaded rods (made from ASTM A 193 steel) which are locked into their respective anchor holes using Energy's MP-3 anchoring compound.

Crash Testing

To test worst case impact conditions, NCHRP 350 test 3-11 was conducted into the 12M Vulcan Barrier anchored using the new VAS. The test system consisted of four freestanding 12M Vulcan segments pinned together and anchored with three VAS straps per 12M Vulcan section. Each VAS strap was held down with two MP-3 threaded rods embedded into concrete or asphalt at a depth that was appropriate per manufactures recommendations. The impact point for this test is identified and the test data summary page is enclosed for reference. The test was successful, with the 2000p vehicle being smoothly redirected at a shallow angle back into the traffic flow. Maximum dynamic deflection of the upper portion of the 12M Vulcan during this anchored test was 300 mm (12 in). You noted that the deflection at the base of the Vulcan Barrier was 76 mm (3 in). NCHRP Test 3-10 was waived as the original Vulcan Barrier was tested using the 820C vehicle.

Findings

Based upon the successful completion of the aforementioned 350 test, we concur that the Energy Absorption Systems' 12M Vulcan Barrier meets the NCHRP Report 350 criteria for Test 3-11. Successful completion of this test qualifies the 12M Vulcan for use on the NHS as TL-2 or TL-3 barrier under the range of conditions tested, when such use is acceptable to a highway agency. We also concur that the Vulcan Barrier Anchoring System is an acceptable anchoring system that can be used where lateral deflection of the barrier must be controlled, with lateral displacement at TL-3 impact conditions expected to range from 76 mm (3 in) to 300 nm1 (12 in). The freestanding, unshielded end of this design is not crashworthy and requires either shielding with a suitable impact attenuator or introduced outside the appropriate clear zone. However we do concur that since the 12M Vulcan has the same design characteristics and end features as the already accepted 4M Vulcan, the same end treatments are also acceptable (reference the FHW A acceptance letter B-134, dated February 14, 2005).

Please note the following standard provisions that apply to FHW A letters of acceptance:

This acceptance is limited to the crash worthiness characteristics of the systems and does not

cover their structural features, nor conformity with the Manual on Uniform Traffic Control

Devices.

- Any changes that may adversely influence the crashworthiness of the system will require a new acceptance letter.

- Should the FHW A discover that the qualification testing was flawed, that in-service performance reveals unacceptable safety problems, or that the system being marketed is significantly different from the version that was crash tested, we reserve the right to modify or revoke our acceptance.

- You will be expected to supply potential users with sufficient information on design and installation requirements to ensure proper performance.

- You will be expected to certify to potential users that the hardware furnished has essentially the same chemistry, mechanical properties, and geometry as that submitted for acceptance, and that it will meet the crashworthiness requirements of the FHW A and the NCHRP Report 350.

- To prevent misunderstanding by others, this letter of acceptance is designated as number B-134C and shall not be reproduced except in full. This letter and the test documentation upon which it is based are public information. All such letters and documentation may be reviewed at our office upon request.

- The Vulcan and 12M Vulcan Barriers are patented products and considered proprietary. If

proprietary systems are specified by a highway agency for use on Federal-aid projects, except exempt, non-NHS projects, (a) they must be supplied through competitive bidding with equally suitable unpatented items; (b) the highway agency must certify that they are essential for synchronization with the existing highway facilities or that no equally suitable alternative exists; or (c) they must be used for research or for a distinctive type of construction on relatively short sections of road for experimental purposes. Our regulations concerning proprietary products are contained in Title 23, Code of Federal Regulations, Section 635.411. - This acceptance letter shall not be construed as authorization or consent by the FHW A to use, manufacture, or sell any patented system for which the applicant is not the patent holder. The acceptance letter is limited to the crashworthiness characteristics of the candidate system, and the FHW A is neither prepared nor required to become involved in issues concerning patent law. Patent issues, if any, are to be resolved by the applicant.

Sincerely yours, /* Signature of David A Nicol*/

|

|||

2 Enclosures

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Figure 1. Summary of Results – Vulcan Barrier Anchoring System NCHRP 350 Test 3-11