Original publication: 2013 National Roadway Safety Awards Noteworthy Practices Guide; FHWA-SA-14-002; 2013

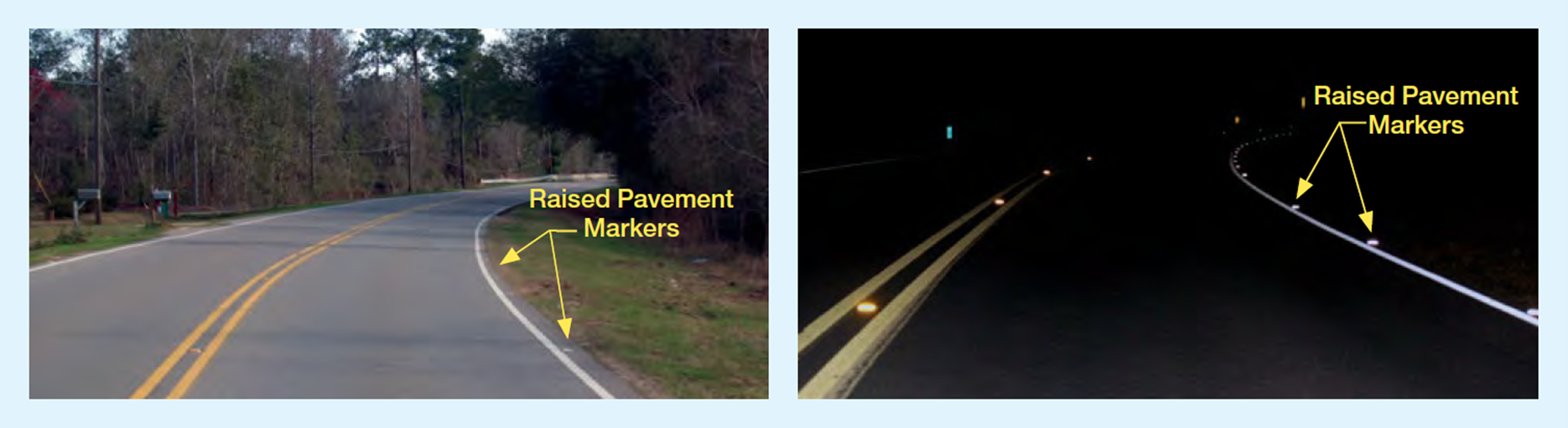

Attaching inspection panel to target sign.

Viewing sign with inspection panel attached

(done at night during actual use).

Describe the roadway safety situation or state before the new practice was implemented. What was the safety issue, problem, or gap?

Three County Highway Departments in western New York did not have access to the necessary equipment for inspecting local signage for compliance with the new Manual on Uniform Traffic Control Devices (MUTCD) sign retroreflectivity standards. In short, there was not enough equipment to inspect the retroreflectivity of all signing in the region.

What were the key challenges that needed to be addressed before the new practice could be implemented?

Required equipment, such as a retroreflectometer, carries a heavy price tag. Without accurate testing equipment, these local counties had to “guess;” erring on the side of caution, the replaced signs that actually might have complied with MUTCD standards (had they been properly inspected).

Describe the new practice:

In the summer of 2011, the Cornell University Local Roads Program (CLRP) initiated a project with the three County Highway Departments and created a sharing agreement so that each agency had access, at a low cost, to a retroreflectometer for inspecting local signing in support of the new Manual on Uniform Traffic Control Devices (MUTCD) sign retroreflectivity standards. This sharing program included all three counties as well as local jurisdictions in the respective counties (i.e., towns, villages, and one city).

In addition to the retroreflectometer sharing agreement, CLRP developed a total of 50 inexpensive sign inspection kits, costing less than $50 each. The kits use clear “overhead projector” sheets in layers to degrade the retroreflectivity of small comparison panels of different colors to a conservative level above the minimum retroreflective levels identified in Table 2A-3 of the MUTCD. The clear overhead sheets are the same ones used with overhead projectors and are available at office supply stores.

List the key accomplishments that resulted from the new practice. Include the roadway safety improvements.

- Improved availability of accurate retroreflectivity testing tools to three local counties, improving sign retroreflectivity quality (and improving compliance with new MUTCD standards) along rural routes.

What technical and/or institutional changes resulted from the new practice?

- Sharing agreement for the retroreflectometer

- Development of a cost effective inspection kit

What benefits were realized as a result of the practice?

The biggest benefit realized were the savings in the form of time and money. In general, the sharing agreement led to a reductions in overtime costs for nighttime inspections, reductions in the number of signs that need to be replaced annually, and an easily compiled, inexpensive ($50) portable field kit that is available at all times.

More specific benefits were:

- More accurate nighttime sign inspections, virtually eliminating “guessing” about the quality of a particular sign (reducing the number of signs that were replaced unnecessarily).

- Example: Wyoming County, New York

- Prior to receiving the kits, sign technicians would err on the side of caution and replace many signs that were actually adequate.

- With the kits, they replaced 20 percent fewer signs than they had replaced previously due to concerns about retroreflectivity.

- Besides being more accurate, retroreflectivity inspections were faster.

- Example: Wyoming County, New York

- Saved a day of overtime, inspecting all the county's signs in only 3 nights.

- From the Wyoming County, New York example: Savings from the reduction of 2 full shifts of overtime work and approximately 30 signs amounts to $3,000 each year.

Is the practice you are submitting from a larger report, journal, or other document? Yes

2013 National Roadway Safety Awards Noteworthy Practices Guide

Publication FHWA-SA-14-002

Contact

David P. Orr, Ph.D.

Cornell Local Roads Program

607-255-8033

David.Orr@cornell.edu