The North Carolina Department of Transportation (NCDOT) started to identify shortcomings in its problem identification method in the mid-1990s. The previous method focused on identifying locations with a potential safety issue based on factors such as crash frequency, crash rate, and crash severity. In many cases, the locations identified did not exhibit a correctable crash type and were congestion related issues. For example, NCDOT repeatedly identified signalized intersections exhibiting a high frequency of rear-end collisions, but attributed the collisions to congestion and driver inattention rather than a roadway factor.

Intersection Warrants:

I-1: Frontal Impact

I-2: Last Year Increase

I-3: Frequency with Severity Index Min

I-4: Night Location without Streetlight

I-5: Chronic Pattern

Section Warrants:

S-1: Run Off Road- Wet Conditions

S-2: Run Off Road

S-3: Wet Road Conditions

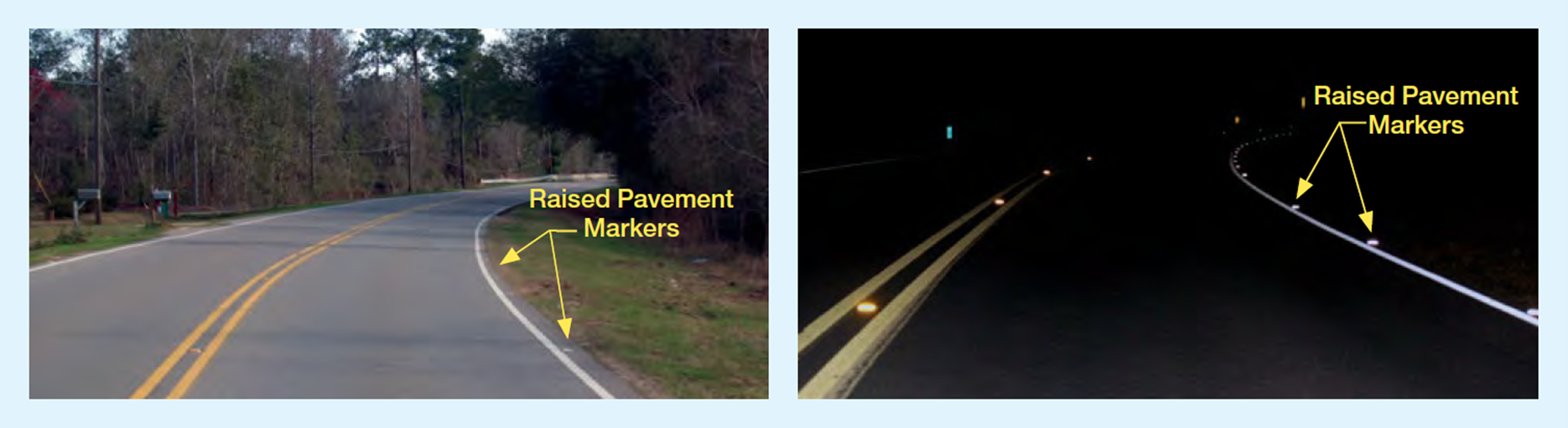

S-4: Non-Intersection Night Location without Streetlight

Bridge Warrant:

B-1: Bridge

Bike/Ped Intersection Warrants:

P-1: Last 3 Years (pedestrians)

P-2: Darkness with Streetlights

P-3: Alcohol Involvement

P-4: Chronic Location

X-1: Last 3 years (bicyclists)

X-2: Darkness with Streetlights

X-3: Alcohol Involvement

X-4: Chronic Location

Beginning with the 1996 HSIP, a set of safety warrants was established for intersections and roadway segments to target locations exhibiting a pattern of correctable crash types or conditions, as well as locations with a significant increase in crash frequency during the past calendar year. NCDOT has continued to expand and modify the safety warrants throughout the years to improve the identification process.

NCDOT initially screens the network (including local roads) for potential safety improvement locations using four categories of safety warrants: intersections, sections, bridges, and bicycle and pedestrian intersections. The safety warrants are analyzed annually using 5 to 10 years of crash data by querying the crash database. The current warrant criteria are based on crash frequency, severity, conditions, and percentage of target crashes. When a location meets the warrant criteria, it is flagged. As an example, an interstate segment would be flagged based on run-off road crashes if a minimum of 30 total crashes occurred on the segment, the crash rate is greater than 60 crashes per mile, and a minimum of 60 percent of the total crashes were run off the road. After a location is flagged, a weighting factor is calculated based on the warrant criteria. The weighting factors are summed for locations meeting multiple warrants and are used to rank locations to determine which will receive priority for further analysis and investigation by the corresponding Regional Traffic Engineering and Highway Division staff. The Regional Traffic Engineers are responsible for identifying potential countermeasures and developing projects.

All safety projects are submitted to North Carolina’s Safety Oversight Committee, which was established to help select projects to receive Spot Safety Program funding. To provide clear and consistent data-driven selection process, the Spot Safety Index (SSI) was developed as a decision support tool to perform an initial prioritization of all candidate projects from across the state. It ensures safety investments are focused on locations with the greatest need and potential for improvement. The SSI is calculated based on a 100-point scale and is composed of four parts: Safety Factor (60 points), Constructability (5 points – e.g., ROW acquisition needs), Department Goals (5 points) and Division/Region Priority (30 points). The Safety Factor is based on the benefit-cost ratio, Severity Index, and whether the project is identified in the HSIP List or identified through a Road Safety Audit (RSA). An initial list of prioritized projects is developed by ranking projects based on the SSI. However, the Committee must take other considerations into account to develop the final list, including distribution of funding to the 14 districts and the effectiveness of countermeasures identified in the projects based on results from the state’s evaluation group.

Key Accomplishments

- Developed network screening method to identify locations with severe and correctable crash patterns.

- Continued to update network screening process to improve the identification of relevant safety issues and locations.

- Developed systematic project prioritization ranking method that considers benefit-cost analysis, departmental and regional priorities, and ease of constructability.

Results

The development of the safety warrants for use in the network screening process has enabled NCDOT to focus their analysis on the identification of locations with severe crashes and crash patterns correctable by infrastructure safety countermeasures. NCDOT also has successfully established a clear and consistent data-driven process for selecting and prioritizing projects for funding.

Contact

Stephen Lowry

Safety Improvement Engineer

North Carolina Department of Transportation

919-773-2892

slowry@ncdot.gov