N 5140.13

| Notice | ||

|---|---|---|

| Subject | ||

| Weld Details | ||

| Classification Code | Date | Office of Primary Interest |

| N 5140.13 | April 24, 1978 | HCC-30 |

- PURPOSE The purpose of this Notice is to alert personnel of the Federal Highway Administration (FHWA) and State highway agencies of a welded detail which is potentially fracture critical.

- BACKGROUND

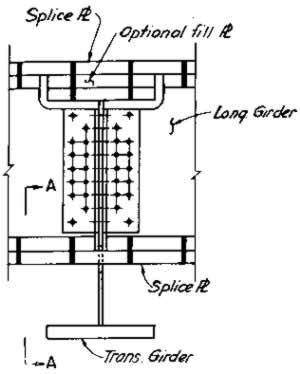

- In instances where structural members intersect, bridges have been constructed that pass one more components of one member through one or more components of the other in order to provide continuity through the intersection.

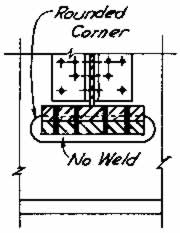

- This type of connection requires that one component be slotted to receive the other. If these slots closely approximate the size of the member passing through the slot, sharp corners can occur at plate edges, providing high stress concentrations. Where the member or component passing through the slot is welded to close the gap, additional stress concentrations are imposed by shrinkage of a highly restrained weld around the periphery of the slot. There is added difficulty in providing a satisfactory weld at the corners of the slot. In the instance where either the member being slotted or the member passing through the slot is in a tension area, the potential for fracture is greater than a Category E detail.

- In instances where structural members intersect, bridges have been constructed that pass one more components of one member through one or more components of the other in order to provide continuity through the intersection.

- RECOMMENDATIONS

- If continuity of one member through another is required and cannot be avoided by placement of one member on top, it is recommended the slotted detail to contain no sharp or reentrant corners and that no welding be done to close the slot. A bolted connection (sketch attached) shows one possible alternate if this type of connection cannot be avoided.

- Each State should be alerted by this Notice to identify and locate these highly restrained details in existing structures. Retrofit action to avoid possible fracture should be considered. Such action should consider careful weld removal or a combination of drilling holes and slotting material to remove the stress concentrations, depending upon the particular detail.

- If continuity of one member through another is required and cannot be avoided by placement of one member on top, it is recommended the slotted detail to contain no sharp or reentrant corners and that no welding be done to close the slot. A bolted connection (sketch attached) shows one possible alternate if this type of connection cannot be avoided.

Associate Administrator for Engineering and Traffic Operations |

Attachment: Section A-A

Last updated: Monday, April 24, 1978